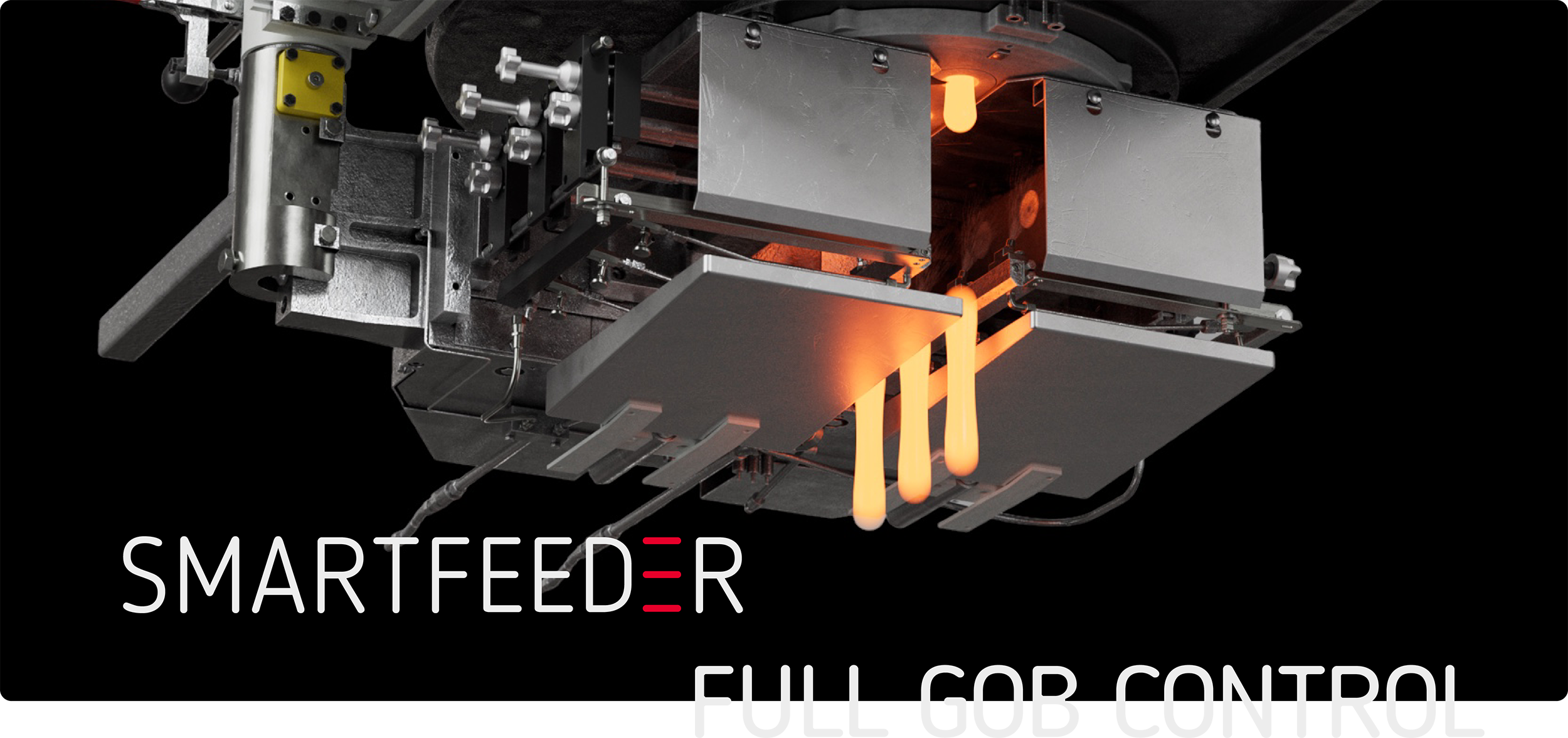

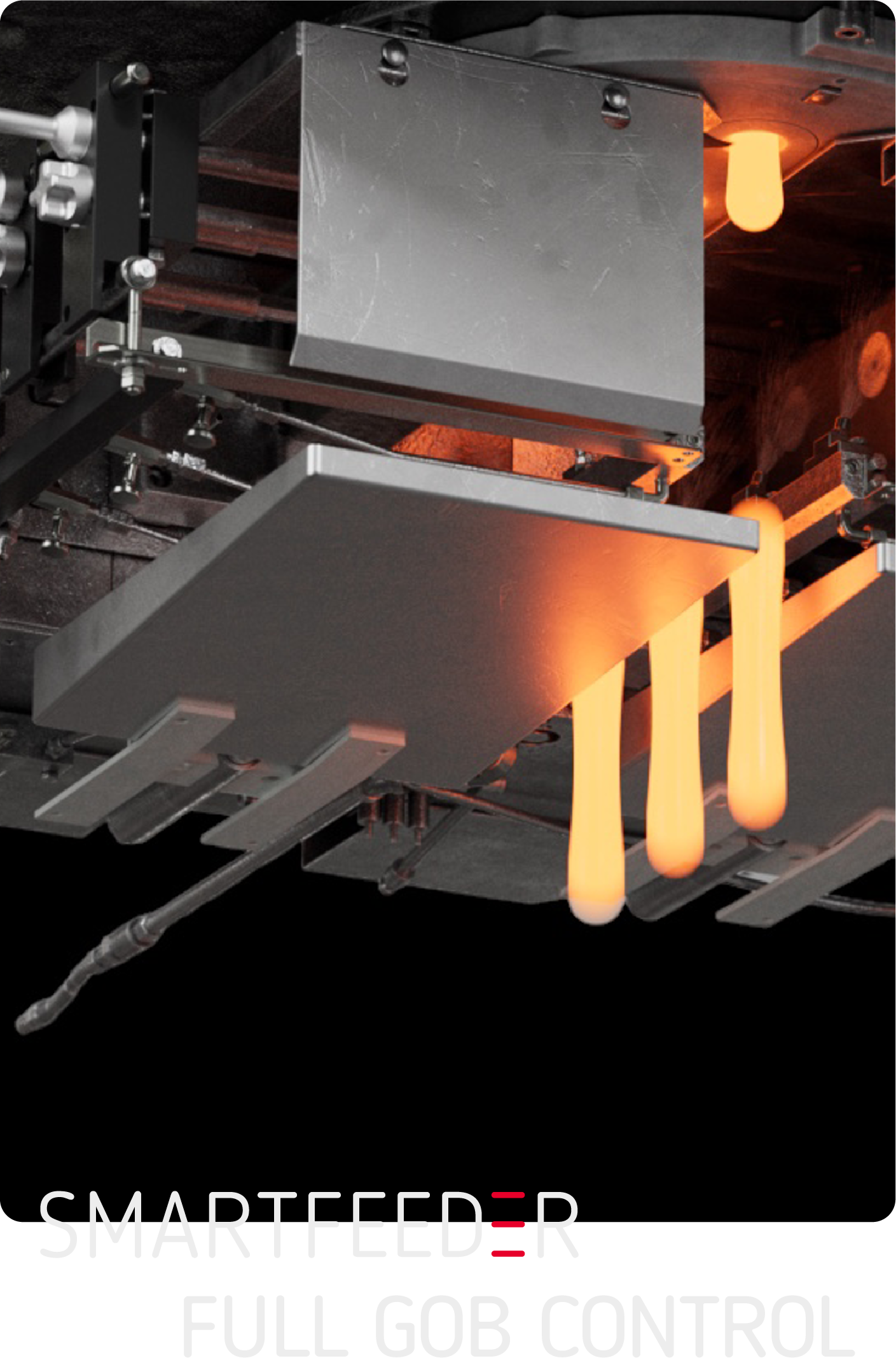

SMARTFEEDER improves process stability, enables easier start-up after job change and facilitates multi-article production.

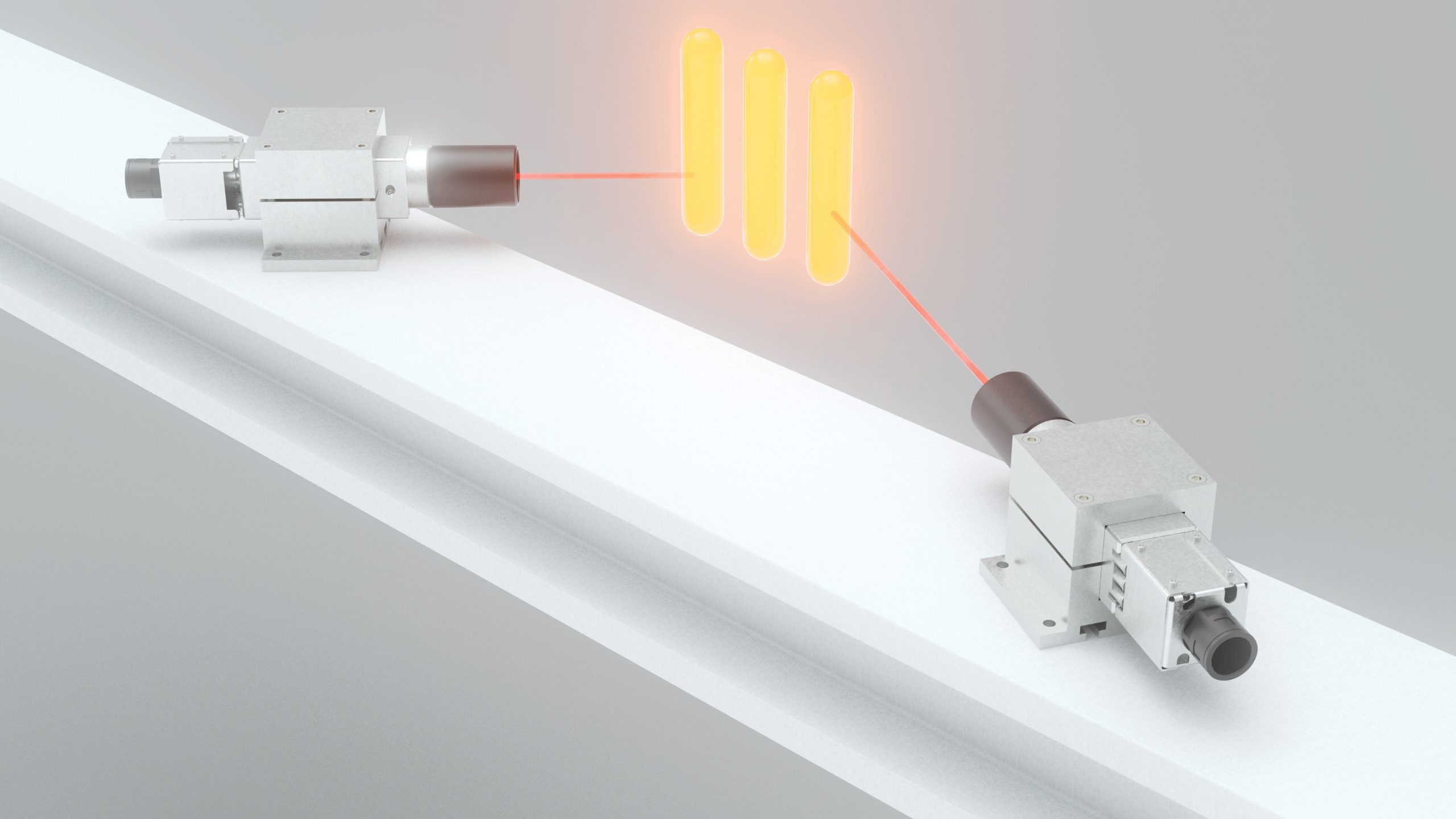

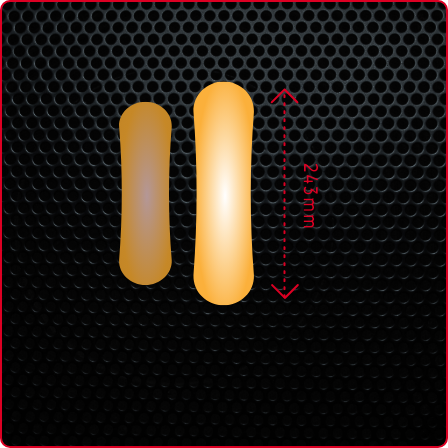

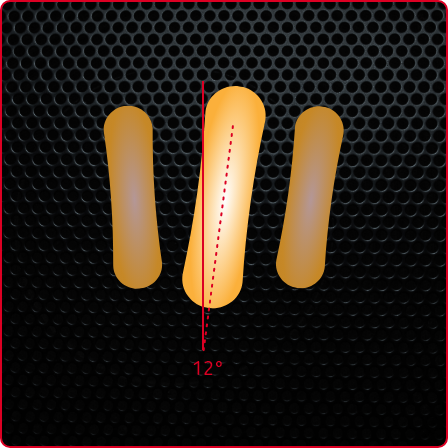

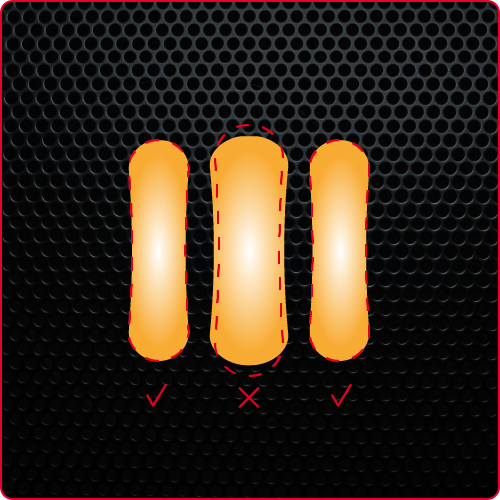

SMARTFEEDER allows you to define parameters for your desired gob design. The Gob Control Closed Loop then adjusts any deviations per cavity and for multi-article production.

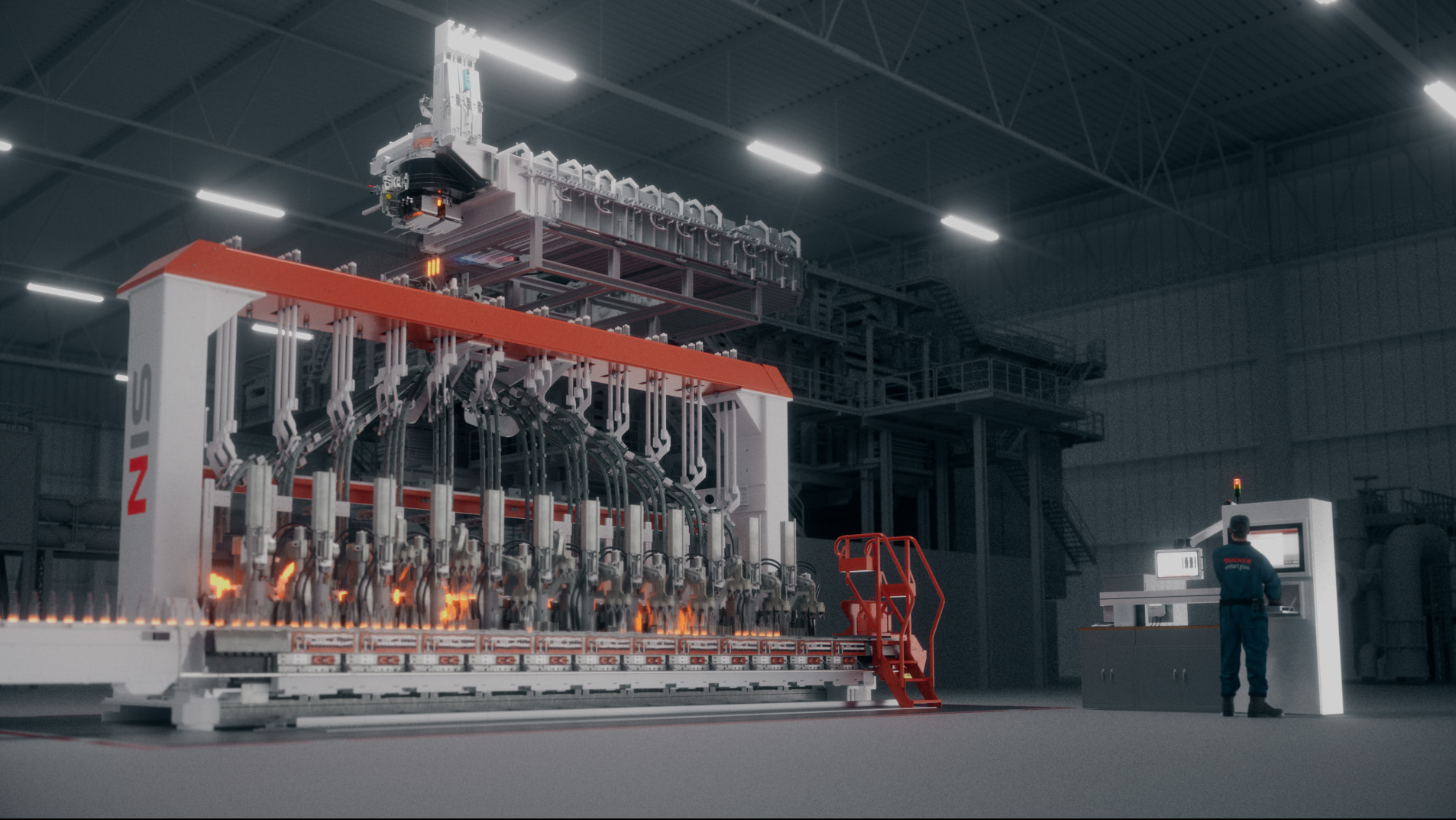

Flexis 3

Flexis 3